Brand :

LinengItem NO :

LN-YS-BZP200Compliance :

CE CertificatePayment :

Credit Card, Paypal, T/T , Western Union, LCWarranty :

Two Years Limited Warranty With Lifetime SupportDelivery Time :

In stockTel :

+86-13506084915Whatsapp:

+86-13506084915Email:

cassie@lionbatterymachine.com1.1 Equipment Overview

LN-YS-BZP200 is a high-precision automatic stacker machine with many advanced functions, which can ensure stable, repeatable and accurate electrode stacking. In its "Z" method of stacking, anode electrodes and cathode electrodes are alternately stacked with a separator between them.

1.2 Workflow

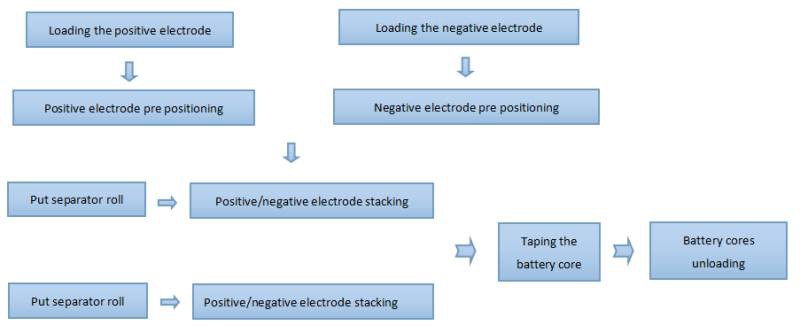

The separator is actively unfolded and guided into the stacking table through a tensioning mechanism. The stacking table drives the separator to move back and forth to place the electrodes. Take the positive electrode and negative electrode out of the two bins on the left by the suction cups of the two sets of manipulators, and stack them on the stacking table after accurate positioning. After stacking, the battery cells are transferred from the robot to the tail roller gluing station. The tail roller is automatic; the separator will be cut off and clicked automatically.

The process flow chart is as follows:

1.3 Equipment features

1.3.1 Separator: active unwinding; tension control; separator deviation correction; separator static removal; separator alignment accuracy ±0.5mm;

1.3.2 High precision: Through the precise positioning of the electrode, the overall accuracy of the electrode in the stack is guaranteed to be ±0.3mm;

1.3.3 High efficiency: stacking speed can reach 0.6s~1s/pcs;

1.3.4 Dust prevention: the material box and pre-positioning device are equipped with effective dust prevention mechanism;

1.3.5 Reliability: The equipment has high precision, and the module of constant speed movement is fixed by positioning pins;

1.3.6 Accurate number of electrode stacks: lack of electrode detection protection; anti-excess electrode sheet mechanism; additional electrode detection mechanism to effectively prevent excess electrodes from accumulating in the battery core.

1.3.7 Electrode tab detection: detect the damaged electrode of the electrode tab and prevent it from being accumulated in the battery cell by mistake.

1.3.8 It can be confirmed according to customer requirements, the material box can be switched through the operation of the manipulator, and the material box can be automatically loaded and unloaded in conjunction with the automatic production line.

1.3.9 It can be confirmed according to customer requirements, and the stacked battery cells can be automatically unloaded to the next assembly line.

2.Standard composition

No. | Components name | Qty/set | Remark |

1 | Automatic feeding mechanism of material box | 2 | Plug-in type special material box, two sets for positive and negative electrodes, size adjustable; |

2 | Electrode loading auxiliary mechanism | 2 | Brush and shaker mechanism; air blowing and dust suction device; prevent extra electrode problem |

3 | Electrode loading and jacking mechanism | 2 | Guarantee the manipulator to absorb the electrodes reliably; automatic shutdown alarm in case of material shortage |

4 | Separator tension control mechanism | 1 | Separator active unwinding, constant tension |

4.1 | Separator correction system | 1 | Unwinding and correcting deviation; |

5 | Mechanical pre positioning module | 2 | Mechanical precise positioning; dust collection device; and equipped with dust collection mechanism |

5.1 | Multipieces detection | 2 | Ultrasonic thickness detection to prevent extra pieces from entering the battery core; |

6 | Stacking manipulator | 2 | Servo drive ensures that the manipulator can grasp and place the electrodes reliably |

7 | Loading suction cup mechanism | 4 | Two sets of vacuum nozzle type and two sets of suction plate type |

8 | Stacking table | 1 | Servo drive stacking table translation and lifting: precise ball screw to realize stacking table reciprocating movement |

9 | Manipulator clamping module | 1 | Manipulator realizes the transfer of battery core automatically |

10 | Separator cut-off mechanism | 1 | One set of hot knife mechanism, cut off after determining the tail coil length |

11 | Adhesive tape side sticking mechanism | 1 | The position and quantity of adhesive on the sides around (including the middle of the tab) can be set |

12 | Automatic unloading mechanism | 1 | Automatic stacking and unloading of battery core, batch removal, reducing manual demand |

13 | Electrical operating system | 1 | Touch screen operation, with emergency stop, power switch and other buttons |

14 | Control system | 1 | Electrical appliances and gas circuits are installed inside the equipment, saving space and easy to maintain |

15 | Rack substrate | 2 | Color: computer grey |

16 | Dust cover | 1 | 1 set of aluminum alloy plexiglass cover, with interlock switch and emergency switch |

17 | Dust suction mechanism | 1 | Blower dust collection; pre positioning, material box |

3.Suitable battery size range(can be customized)

Item | Specification(mm) |

Battery core length L | 135-190 |

Battery core width W | 80-150 |

Battery thickness T | 3.5-20 |

Tab length | 6-20 |

Battery core sketch | |

| |

4. Technical parameters

Item | Specification |

Single stacking time | 0.65s~1.3s(Related to the size of the electrode) |

Single cell auxiliary time | ≤10S |

Accuracy of adjacent electrode and separator | Center deviation±0.5mm |

Separator end face alignment accuracy | ±0.4mm(except the tail roll separator) |

Alignment accuracy of adjacent electrode | ±0.3mm |

Overall alignment accuracy of electrode | ±0.3mm |

Stacking number | It can be set within the thickness range |

Unloading | Pile up the battery cores and unloading |

Crop mobility | 95% |

Pass rate | 98% |

Overview and schematic diagram of the whole machine

Item | Specification |

Machine dimensions | 1700mm(L)×2350mm(D)×1877mm(H) (the size shall be subject to the final design) |

Machine weight/bearing | About 1000KG;> 450kg/m2 |

Power supply | AC220V±10%;single phase; Power:3KVA;frequency:50Hz |

Compressed air | 0.5~0.7MPa(5kgf~7kgf/cm2);Consumption:200L/min;dry air |

Temperature/humidity | 5~35℃;5~55% |

Air/dust | No salt gas, toxic and corrosive gas; no conductive dust |

Magnetic field and vibration | There shall be no magnetic boundary affecting the device; there shall be no impact and obvious vibration |

General model diagram |

|

Hot Tags: pouch cell automatic stacking machine, suppliers, manufacturers, factory, customized, price, discount, for sale, battery automatic winder, Lithium Battery Electrolyte, 256 Channel Battery Capacity Tester Machine, sealer for pouch cell, pouch cell electrode stacking machine, Supercapacitor Sealing Machine

Quanzhou Lineng Mechinery and Equipment Co., Ltd is a technology-based enterprise, integrating R&D, manufacturing, sales and service. Our company has strong scientific research strength, including more than 20 senior mechanical and electrical engineers, 8 external experts and professors, and more than 160 front-line technical workers.