Brand :

LinengItem NO :

LN-PCDCompliance :

CE CertificatePayment :

Credit Card, Paypal, T/T , Western Union, LCWarranty :

Two Years Limited Warranty With Lifetime SupportDelivery Time :

In stockWhatsapp:

+86 18659217588WeChat:

18659217588Email:

cassie@lionbatterymachine.comFeatures

Electric powder press is widely used in the fields of new materials, superconductivity, powder ceramics, new power supply, batteries, building materials, metallurgical powder, etc. it can be used for calcium iron analysis, infrared spectroscopy (IR), X-ray fluorescence (XRF) analysis instrument is used together; the machine is compact in structure, light in weight, fast in pressure rise, simple in operation, safe and convenient; special tablet pressing die is selected, which can be used to press potassium bromide (KBr), sodium chloride (NaCl), cement and other powder materials into various test pieces, columns, heteromorphic bodies or combinations for analysis and research; at the same time, the machine is also suitable for other workers who need corresponding pressure For occasions, as a press, testing the pressure resistance of various objects and so on.

Technical parameters

Model | LN-PCD-40S | LN-PCD-65S | LN-PCD-100S |

Pressure range | 0-40T | 0-65T | 0-100T |

Piston diameter (Chrome plated cylinder) | Φ130mm | φ160mm | Φ200mm |

Maximum piston stroke | 50mm | 50mm | 50mm |

Holding Time | 1S~ ∞S | ||

Display Screen | 7 inches Touchscreen | ||

Safety shield | Acrylic Glass | ||

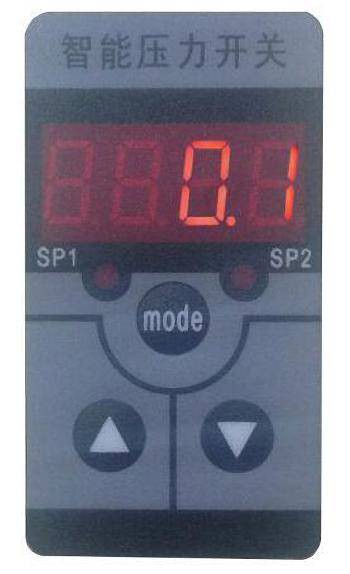

Pressure display display | 0.1ton | ||

Pressurization Process | 20-stage programmed pressurization with pressure profile display | ||

Pressure holding time | Each stage can be up to 32,768 seconds or run indefinitely without timing | ||

Pressure conversion | Automatically calculate the pressure exerted on the sample based on its shape and | ||

Number of columns | FOUR | ||

Pressure Protection | With Pressure Overload Protection Function | ||

Gradual Pressurization Function | Programmable Gradual Pressurization Speed | ||

Power of power supply | 1500W (220V/110V Customizable) | ||

Diameter of worktable | φ140mm | φ170mm | Φ210mm |

working space | 220×300mm | 220×300mm | 260×250mm |

Tablet Press Dimensions/Net Weight/Gross | 352x420x510mm | 400x470x560mm | 390x260x1090mm |

Controller Dimensions/Net Weight/Gross Weight | 350x460x480mm | 350x460x480mm | 350x460x480 mm |

Remarks | If you need extra mould, please contact the sales manager for further quote. The work space can be customized to increase the height | ||

Model | LN-PCD-150S | LN-PCD-200S | LN-PCD-300S |

Pressure range | 1-150T | 0-200T | 0-300T |

Piston diameter (Chrome plated cylinder) | φ250 mm | Φ290mm | Φ380mm |

Display Screen | 7 inches Touchscreen | ||

Safety shield | Acrylic Glass | ||

Pressure display display | 0.1 ton | ||

Pressurization Process | 20-stage programmed pressurization with pressure profile display | ||

Pressure holding time | Each stage can be up to 32,768 seconds or run indefinitely without timing | ||

Pressure Conversion | Pressure Conversion Based on Sample Shape | ||

Data Analysis | It can be opionally connected to a computer to perform functions suchas data recording,analysis,comparison,modification.and export. | ||

Number of columns | SIX | EIGHT | EIGHT |

Pressure Protection | With Pressure Overload Protection Function | ||

Gradual Pressurization Function | Programmable Gradual Pressurization Speed | ||

Power of power supply | 1500W (220V/110V Customizable) | ||

Diameter of worktable | Φ260mm | Φ300mm | Φ390mm |

working space | 285×290mm | 290×300mm | 400×450mm |

Tablet Press Dimensions/Net Weight/Gross | 950x 600 x 1000 /723kg/793 kg | 1000x650x1050mm | 620x680x1280mm |

Controller Dimensions/Net Weight/Gross Weight | 350x460x480 mm /109 kg/ 126 kg

| ||

Remarks | If you need extra mould, please contact the sales manager for further quote. The work space can be customized to increase the height | ||

Pressure Conversion Table | |

Actual pressure | System pressure |

1 T | 0.56 MPa |

3 T | 1.70 MPa |

5 T | 2.80 MPa |

10 T | 5.60 MPa |

20 T | 11.3 MPa |

30 T | 17.0 MPa |

40 T | 22.6 MPa |

50 T | 28.3 MPa |

60 T | 34.0 MPa |

Pressure calculation formula | Area of oil cylinder / area of mould x reading of pressure gauge = actual pressure of mould |

NOTE | Generally, the system pressure should not exceed 31.4mpa, otherwise it will affect the service life of the equipment and cause oil leakage |

Related Products

Hot Tags: electric hydraulic press machine, suppliers, manufacturers, factory, customized, price, discount, for sale, pouch cell ultrasonic welder, Battery Stacking Machine For Production, Coin Cell Electrode Disc Punching Mahcine, Laboratory Coating Machine, sealer for pouch cell, cylindrical battery assembly machine

Quanzhou Lineng Mechinery and Equipment Co., Ltd is a technology-based enterprise, integrating R&D, manufacturing, sales and service. Our company has strong scientific research strength, including more than 20 senior mechanical and electrical engineers, 8 external experts and professors, and more than 160 front-line technical workers.