Brand :

LinengItem NO :

LN-6018Compliance :

CE CertificatePayment :

Credit Card, Paypal, T/T , Western Union, LCWarranty :

Two Years Limited Warranty With Lifetime SupportDelivery Time :

In stockWhatsapp:

+86 18659217588WeChat:

18659217588Email:

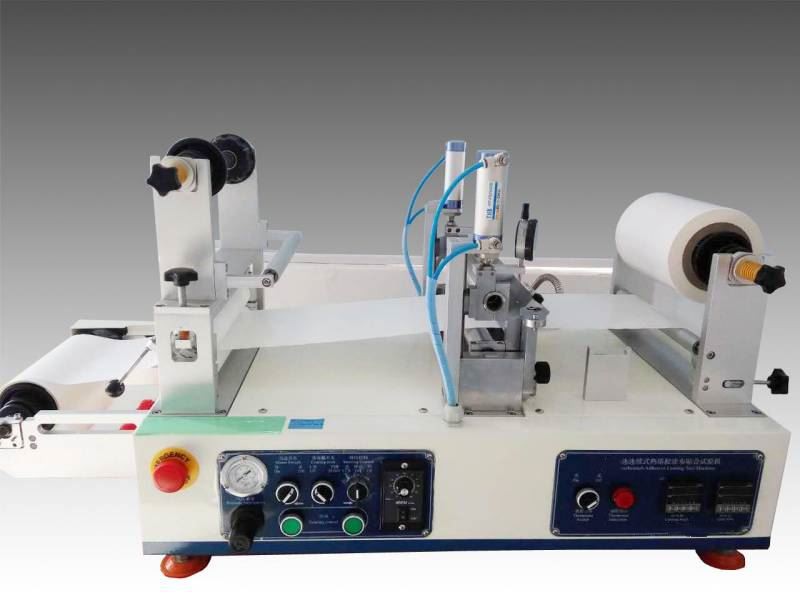

cassie@lionbatterymachine.comLN-6018 continuous hot melt adhesive coating and laminating machine is a laboratory mini-type hotmelt adhesive coating and laminating machine which can be manufactured insmall quantities and assembled by the mechanism of high precision modular coating station.Hot melt pressure sensitive adhesive can be directly coated on heat resistant substrate,or coated on the release paper and then theadhesive film to paste on different surface materials,such as paper, plastic model metalfilm, etc. (the best experimental substrate recommended to use 50 micron high temperature PET film).

Performance characteristics

Structure | High precision modular coating station structure assembly |

Maximum operating temperature | 200℃ |

Temperature control mode | Independent pt-100 high-precision PID temperature control mode for the upper rubber wheel and rubber groove |

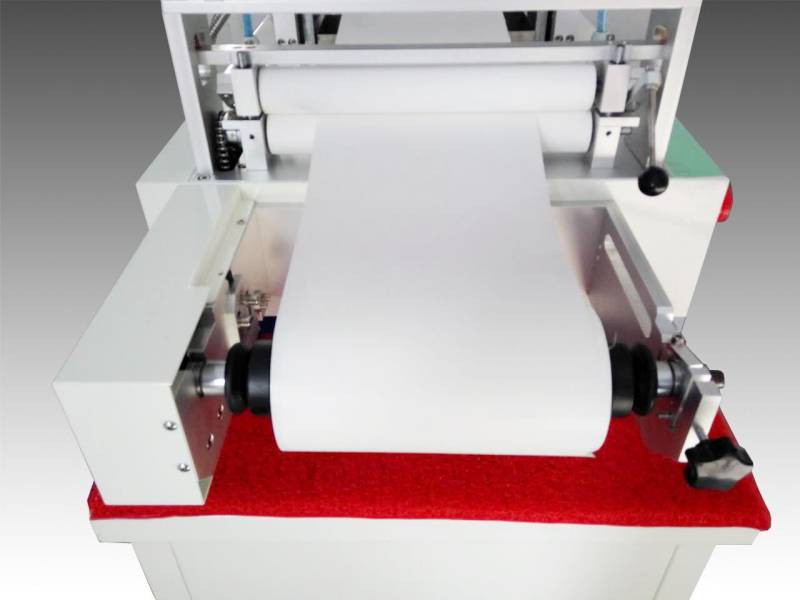

Coating method | Use the micrometer as the dividing head to precisely adjust the coating gap between the upper and lower rubber wheels to control the coating thickness.The maximum coating gap is 500 microns (substrate thickness), and the optimum coating thickness is ≥20 microns (coating accuracy is ±5 microns).After the thickness setting, the rubber wheel can be indirectly locked to prevent the gap from changing |

Coating width | The maximum width of the coil is 200mm (the maximum width of the sheet is 260mm) and the maximum coating width is 160mm.The coating width is adjusted by two Teflon baffles in the glue tank.Unlimited length of adhesive coating, automatic winding. |

CVT, maximum coating speed | 4.5m/min (optimal coating speed is 1-2m/min) |

Release reel | Can adjust knob to change tension release |

Material receiving reel | Can adjust the mechanical tension control |

Remove residual glue | Heating rod, rubber wheel and rubber groove can be quickly removed from the body to remove residual glue. |

Machine size | 1150 * 518 (including 720 motors) * 658 mm (length * width * height) |

Machine weight | about 120 kg |

Power supply | AC 220v (single-phase)/50Hz |

Machine power: | 1050W |

Hot Tags: coating and laminating testing machine, suppliers, manufacturers, factory, customized, price, discount, for sale, Coin Cell Spring, Pouch Cell Lab Assembly Line, Laboratory Semicircular Planetary Ball Mill, roll to roll coating machine, Hot Melt Adhesive Tape, 8 channel cylindrical battery analyzer

Quanzhou Lineng Mechinery and Equipment Co., Ltd is a technology-based enterprise, integrating R&D, manufacturing, sales and service. Our company has strong scientific research strength, including more than 20 senior mechanical and electrical engineers, 8 external experts and professors, and more than 160 front-line technical workers.